Houston Upper Braes Lift Station Rehabilitation (70 MGD)

- Local Governments

- Public Utilities

Market

- Engineering

- Wastewater

- Water

Services

- Houston, Texas

Locations

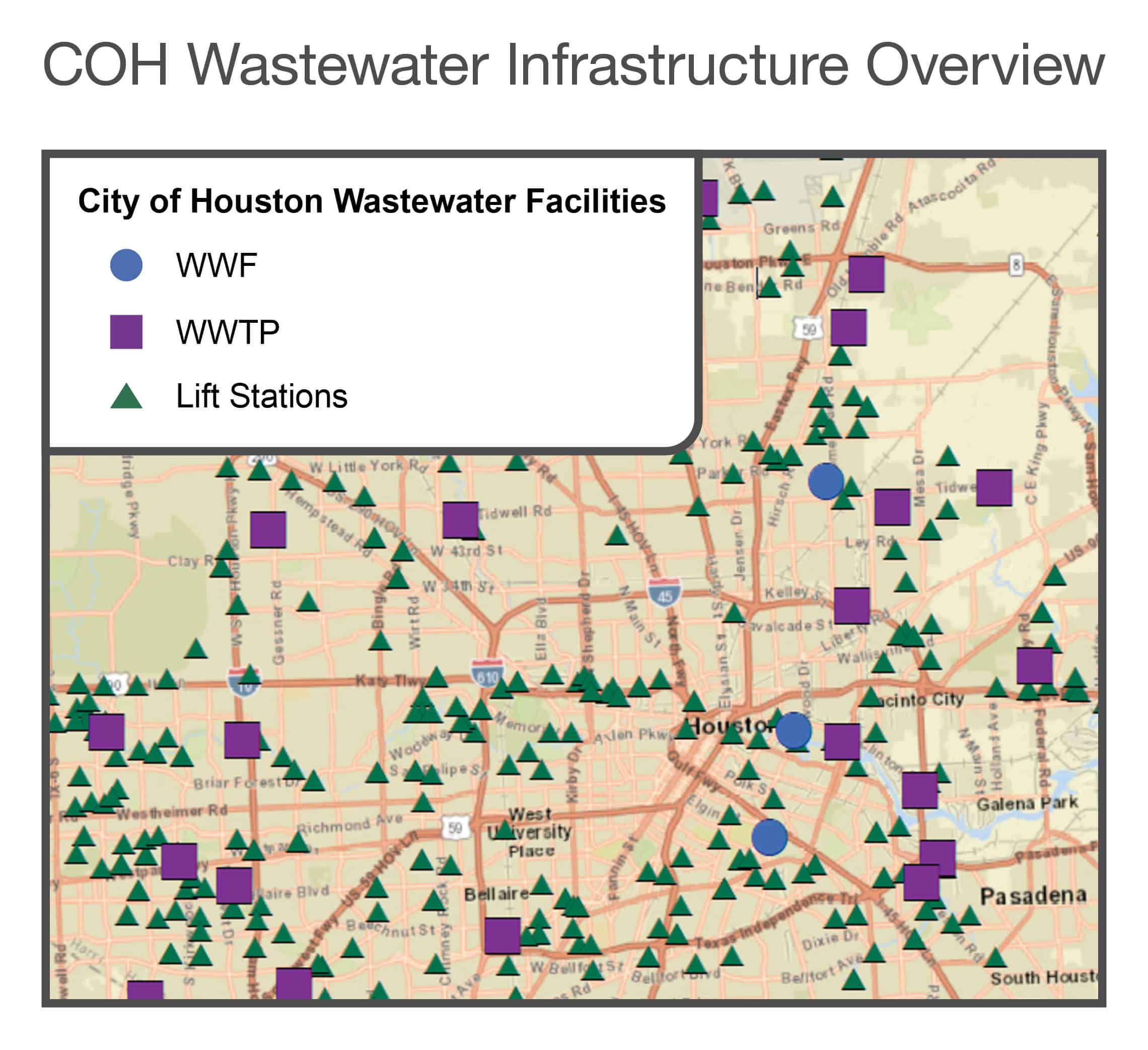

The lift station located at the City’s Upper Braes WWTP had not undergone improvements for over 30 years and was starting to experience structural and mechanical piping corrosion issues. To avoid costly replacement, the City looked to HR Green to identify improvements that could prevent future failures and extend the life of the system. In addition to the lift station rehabilitation, the design project included the replacement of all piping (24” and 30” force mains) as well as all Electrical and Instrumentation & Controls for the Lift Stations. HR Green performed preliminary engineering and final design engineering services and currently performing construction phase engineering services for the project.

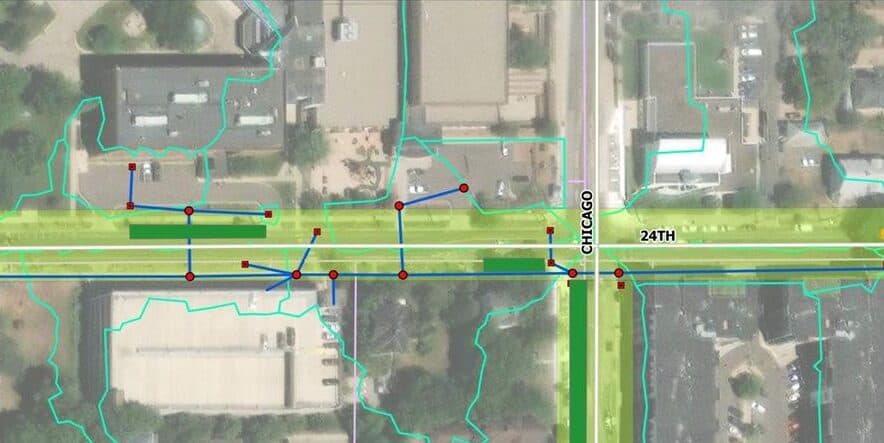

This lift station (LS) handles flow from a large service area, with the gravity conveyance ending at the lift station being a 108-inch reinforced concrete pipe and approximately 70 feet below grade. Isolation of the 108-in pipe is via a 70-foot deep influent access bypass shaft upstream of the LS. The LS is split into two wet wells; the upper and lower chamber. The upper chamber is approximately 40 feet deep, has four 6,300 gpm pumps, each with a 24” force main, and occupies the top quarter of the structure. The lower chamber is approximately 80 feet deep, has six 9,000 gpm pumps, each with a 30” force main, and occupies the remaining three-quarters of the structure. All ten force mains discharge into an annular channel outside the wet well which conveyed the flow to the WWTP headworks structure.

During the Preliminary design, HR Green evaluated lining systems for the lift station wet well to protect the structural concrete from the corrosive effects of wastewater. The team recommended material coatings for the wall that would supply protection to the lift station. The recommended lining material had to be compatible for use in vertical and horizontal applications and require minimal curing time to limit LS downtime and bypass pumping costs. HR Green also identified necessary piping, electrical, and structural improvements. As the pumps were relatively new, those were the only pieces of equipment not replaced.

During the lift station rehabilitation final design, HR Green participated in multiple meetings with the client to coordinate bypass pumping efforts and finalize construction sequencing to minimize LS downtime and bypass pumping costs. Bypass of the wet well lower chamber required the installation of stop logs inside the influent access bypass shaft and coordinating levels in the shaft to limit surcharging in the sanitary sewer collection system. Construction sequencing accounted for the electrical work (480V and 4160V service) as well as other work required.

As part of the construction, HR Green coordinates with the Contractor to ensure the proposer staging of bypass pumping to mitigate sanitary sewer overflows while stabilizing pumped flows to the WWTP to minimize flow surges and disruptions to WWTP processes. The team provided process mechanical engineering and structural engineering and oversaw its subconsultant teaming partner’s improvements for electrical engineering.