Navigating Biosolids Management: A Comprehensive Approach

For many wastewater facilities, treatment residuals costs are one of the highest expense items in the budget.

Biosolids (stabilized sludges) generally comprise the largest fraction of treatment residuals. A comprehensive evaluation and understanding of biosolids management offers an opportunity to improve the efficiency and economics of this process.

Elements of biosolids management include production, processing, storage, and disposal. Operational considerations and costs within these elements must be evaluated and understood. A biosolids management study should include a quantitative and qualitative analysis of these elements, resulting in a biosolids management plan to best meet a facility’s current and future needs.

(To access a PDF version of the white paper, download the file via the form above.)

Completing a Biosolids Analysis

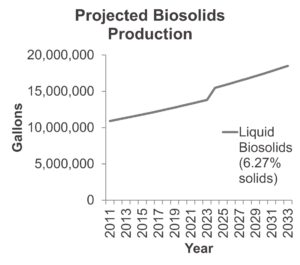

A biosolids production analysis helps forecast quantities for the design period. The evaluation should consider:

- Changes in sludge treatment efficiency (increase or decrease)

- Future population growth/loading

- Increased sludge production due to nutrient removal processes

- Chemical sludge production

A thorough review of historical production records, growth projections, and an understanding of future treatment needs is necessary. Accurate forecasting of production quantities establishes the basis for analysis of all other elements in a biosolids management study.

A facility may include some form of biosolids processing depending on storage needs, end product use, or both. Generally, processing takes the form of dewatering and/or drying to reduce the volume of biosolids and to create a semi-solid and solid end product.

Importance of Post-Stabilization Processing

The purpose of post-stabilization processing is to reduce the volume of biosolids to store and dispose of by removing water from the biosolids. Volume reduction can result in significant biosolids management capital and operations and maintenance cost savings.

Biosolids total solids concentration is approximately one (1) percent (by weight) prior to any post-stabilization processing. Dewatering can typically achieve an increase in biosolids total solids concentration to between 18- and 30-percent (by weight).

The dewatering process is aided using polymers to bind solid particles and release free water in the biosolids matrix. Drying can further increase biosolids total solids concentration to between 90- and 98-percent.

There are multiple process equipment/technology options for dewatering, including:

- Belt filter press

- Rotary fan press

- Screw press

- Centrifuges

- Plate and frame press

- Gravity bag systems

|

|

|

Drying must be preceded by dewatering in all scenarios. Additionally, drying produces a Class A biosolids product that has many benefits over a Class B biosolids product. Drying equipment/technology includes two general categories: Direct or Indirect. Each has widely varying configurations and layouts between manufacturers’ systems.

Along with equipment sizing, dewatering and drying alternative analysis should consider:

- Operations, maintenance, and replacement costs for each option

- Required ancillary systems and associated operations and maintenance (e.g. feed pump(s), wash water system, polymer system, etc.)

- Complexity of operations and maintenance

- Labor availability and potential for process automation

- Environment (equipment indoor or outdoor installation, available equipment space, etc.)

- Redundancy needs

Choosing Biosolids Storage

There are numerous options for biosolids storage; however, storage configuration and size are influenced by the following factors:

- Biosolids type (liquid, dewatered, dried)

- Disposal frequency/schedule

- Space availability

Storage capacity should include a contingency above the calculated biosolids production volume (e.g. extra 15-percent volume). This extra capacity will provide a safety factor in the event biosolids disposal is delayed due to unfavorable conditions, equipment breakdown, etc.

Storage facility design must also include considerations for the “protection” of the biosolids product. A dewatered and dried biosolids product should be protected from environmental elements (i.e. precipitation); otherwise, the dewatering and drying effort and expense is wasted!

Storage facilities should incorporate means for access and cleaning for efficient operations. Liquid biosolids storage facilities may also consider means of mixing contents to aid with effective removal and to produce a homogeneous product for disposal, especially after long storage times.

Disposal of Biosolids

Ultimately, biosolids require disposal and final disposal methods can include:

- Landfilling

- Land application

- Soil amendment

- Incineration

Ideally, disposal methods that have a beneficial reuse of the biosolids product are preferred. Biosolids disposal methods are highly regulated and subject to biosolids’ classification and makeup. There are emerging contaminants of concern that may impact biosolids disposal options in the future (e.g. PFASs/PFOAs, pharmaceuticals, etc.)

Disposal costs can vary widely depending on the type of biosolids and disposal method selected. In general, labor and transportation costs are the factors with the greatest impact to disposal costs. There are some facilities that have turned biosolids disposal into a revenue stream to offset costs.

Many facilities use third parties for disposal. Disposal efforts can be significant and may impact other facility operations. The following are considerations for disposal operations and decisions:

- Resource effort and availability (labor)

- Equipment needs (purchase or lease)

- Safety, liability and risk

The Economics of Biosolids Management

Each element of biosolids management contains an operations component. Evaluating and selecting the best use of resources to meet operational objectives of a facility is the desired outcome. Life-cycle operations and maintenance (O&M) costs must be included for a complete quantitative economic evaluation. Many times, low capital cost alternatives have high life-cycle O&M costs. Initially, these alternatives appear more attractive than higher capital cost alternatives, but in the long term, they are more expensive.

- Safety, liability and risk

- Public perception

- Beneficial reuse and sustainability

- Flexibility

A scoring or ranking criteria should be developed to help “score” or “rank” the non-economic factors. A facility must also decide the relative importance of non-economic factors with respect to economic factors for guidance in making decisions to create the biosolids management plan.

A Comprehensive Approach to Biosolids Management

Biosolids management is a multi-layered and interconnected process. A holistic evaluation focusing the best use of resources to meet both economic and non-economic objectives of a facility is key for creating a sustainable biosolids management plan.

In navigating the intricacies of biosolids management, it’s often invaluable to collaborate with professionals who understand the nuances of wastewater planning and sustainable solutions. At HR Green, our dedicated water and wastewater planning teams possess a wealth of knowledge and experience in developing effective biosolids management strategies. We’re here to assist you in optimizing your approach, whether it’s minimizing costs, maximizing sustainability, or addressing specific challenges unique to your facility.

Let’s embark on this journey towards efficient and sustainable biosolids management together. Connect with our team today to explore tailored solutions for your facility’s needs.

Subscribe to HR Green Insights

We're dedicated to providing up-to-date knowledge and insights about the topics that matter most to you. We know how busy you are, so we will keep this simple, covering just one topic per email. Once you've subscribed, you can easily customize your preferences to receive only the updates relevant to you.