Burlington's Wastewater Treatment Facility Improvements

- Economic Development

- Local Governments

Market

- Construction

- Engineering

- Wastewater

- Water

Services

- Burlington, Iowa

Locations

A major industry proposed to locate a facility in the City of Burlington, IA, but the City was not able to offer the wastewater treatment capacity desired by the industry. Losing the potential development opportunity resulted in the City’s decision to move forward with the major wastewater treatment facility improvements to prepare for future economic development opportunities. The improvements focused on organic and solids handling capacities.

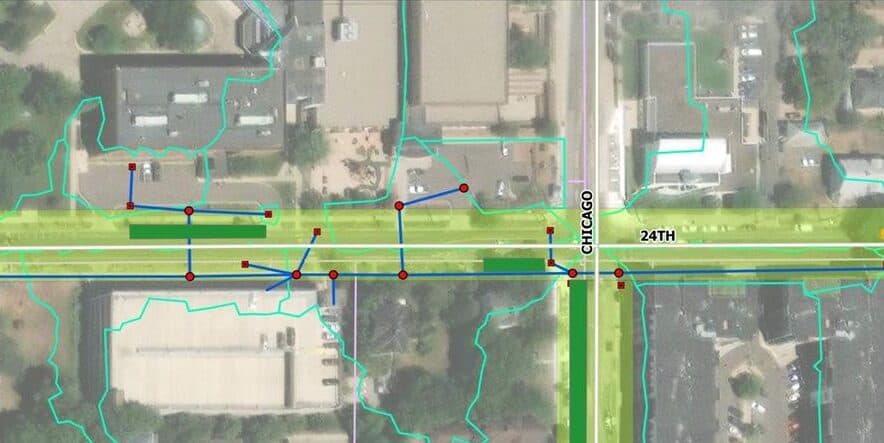

HR Green was retained by the City to provide preliminary and final design services. Technical memorandums were prepared to review many design aspects including primary clarification and anaerobic treatment options. Innovative alternatives including temperature phase anaerobic digestion (TPAD) and beneficial gas reuse and energy recovery were evaluated.

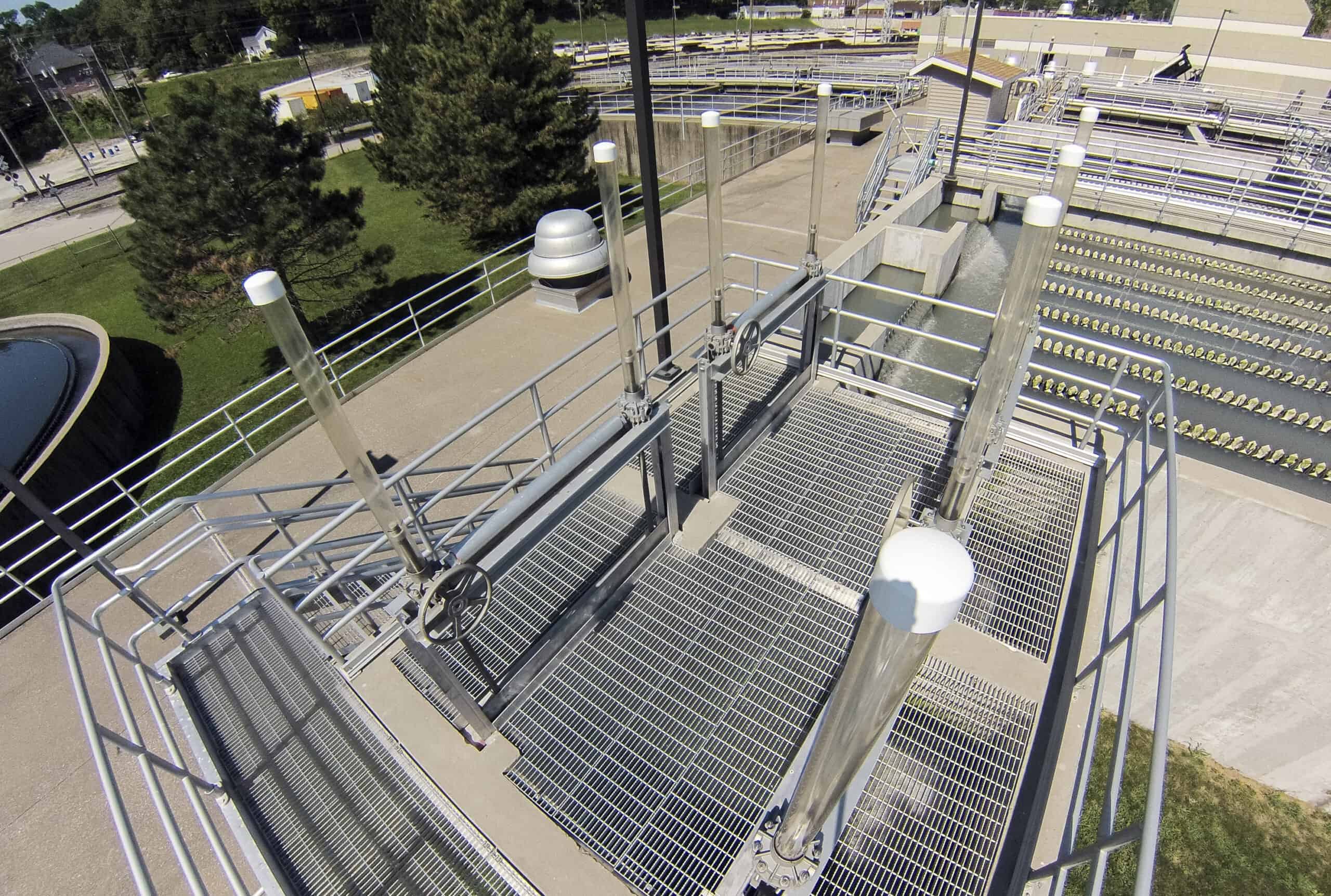

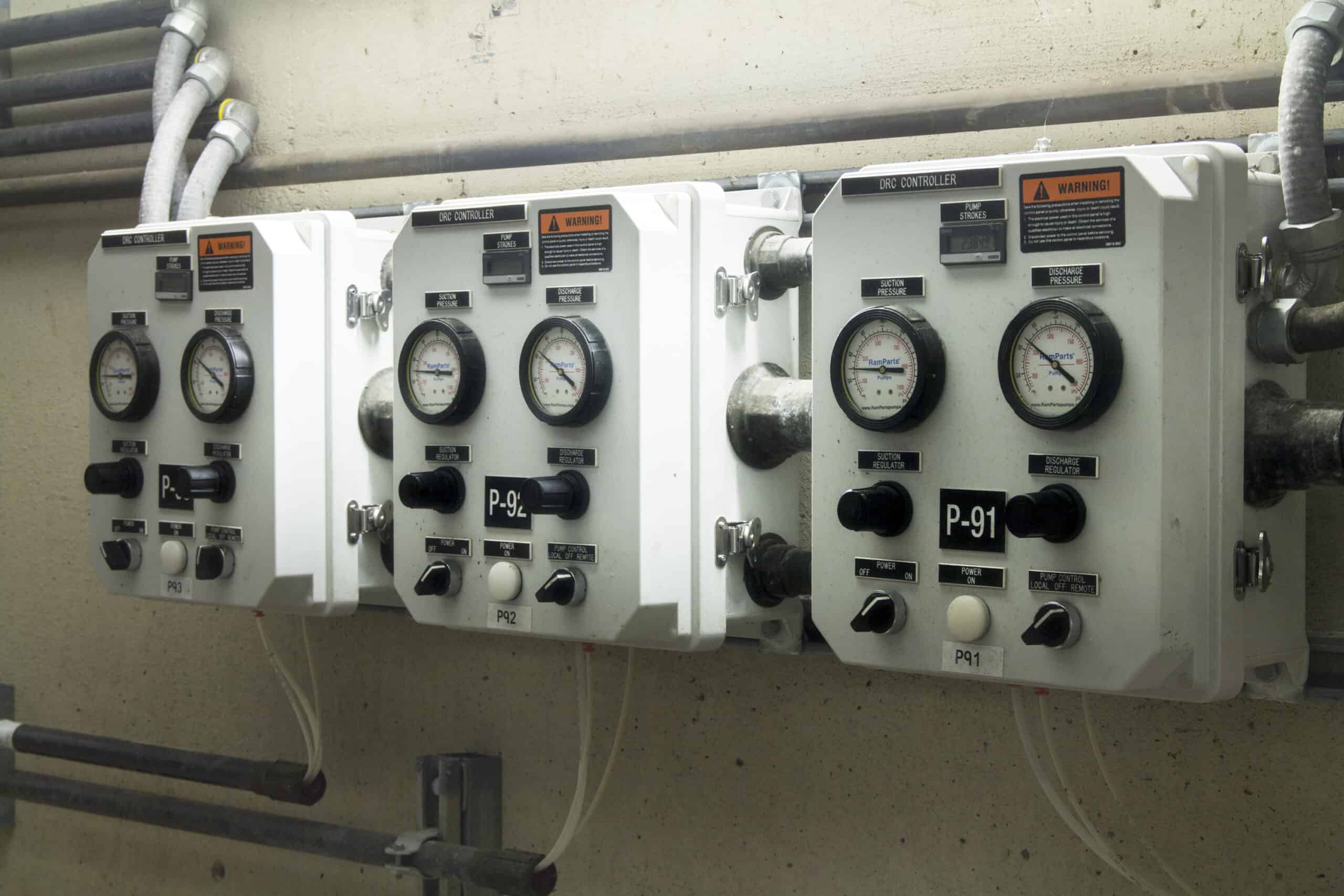

The wastewater treatment facility improvements included multiple liquid treatment processes and anaerobic digestion facilities. The existing aerobic digester was converted to an anaerobic digester by installing a cover and gas collection/mixing system. The digester is 75-foot diameter with a 24-foot sidewater depth. Accommodations were made in the design to allow for future conversion to a TPAD digestion process. The primary and thickened waste-activated sludges are blended together and then consistently fed to the anaerobic digester for stabilization. The digester is heated with dual-fuel boilers and water-to-sludge heat exchangers. Three (3) external draft tube mixers provide mixing and sludge contact to the hot water jacket heat exchangers. Excess digester gas is used to heat water and be distributed to offset plant heating needs. The project included various modifications to existing piping and pumping systems in very confined areas.

The Burlington project required very specific construction sequencing to keep the plant operational and meeting NPDES permit requirements for the duration of the project. The specifications detailed complex construction processes for the contractor to follow. The sequencing considered expected wet-weather, river flooding, durations for processes being offline, durations for construction work, contingency plans, etc. The sequence was followed by the contractor and provided a smooth construction process.