Deciding whether to rehabilitate or replace a lift station is one of the most important infrastructure decisions a utility can face. The choice involves balancing conditions, cost, performance, and long-term reliability. Without a structured evaluation process, utilities risk overinvesting in repairs or ignoring obsolete components or undersized infrastructure that keep O&M costs high.

At HR Green, we guide municipalities through a proven, repeatable assessment process that helps leaders make confident, data-driven decisions. A thorough condition assessment lays the groundwork for a well-informed rehabilitation or replacement strategy. Understanding and weighing key criteria, such as system age, performance data, and future capacity needs, helps determine the most effective path forward for your community.

Conducting a Lift Station Condition Assessment

A comprehensive condition assessment is the cornerstone of effective asset management. It provides the facts needed to prioritize investments and plan for the future. When HR Green’s engineers evaluate a lift station, we examine several core categories, including structural, mechanical, electrical, HVAC, operational, and safety.

Structural Assessment

A sound structure is essential for safe operations and long-term reliability of the lift station. We review the wet well and building for cracking, corrosion, leaking joints, water intrusion, and deterioration of coatings or linings. Structural assessment also considers concrete condition, wall integrity, and any deficiencies that could impact safety, infiltration, or hydraulic performance.

Mechanical Assessment

Mechanical equipment drives station performance, so identifying wear or functional issues early helps prevent failures and costly emergency repairs. We evaluate pump health, clog frequency, vibration, noise, bearing conditions, and how pumps operate under load. Pump drawdown testing can be performed to compare actual pump performance to the original pump curves. We also review valves, piping, mixing systems, and any observed hydraulic inefficiencies.

Electrical and Controls Assessment

Reliable electrical and controls systems are critical for continuous operation and safe maintenance. We assess the age, condition, and code compliance of control panels, MCCs, SCADA components, alarms, and backup power systems. This includes verifying arc-flash labeling, surge protection, grounding, and whether the equipment can be safely accessed and maintained per modern standards.

HVAC Assessment

Proper ventilation and heating protect equipment and provide safe working conditions, especially in dry-pit pump rooms or control buildings. We inspect the functionality of ventilation fans, heaters, ductwork, and dehumidification. Many older stations have inadequate HVAC that fails to meet NFPA requirements, leading to moisture issues, corrosion in electrical panels, and shortened equipment life.

Operational Assessment

Understanding how the lift station performs day-to-day helps identify bottlenecks and improvements that can reduce maintenance effort. We observe operating cycles, pump sequencing, control setpoints, alarm history, and any operator workarounds. This helps reveal whether the station is meeting current flow demands and whether operational changes or equipment upgrades could improve reliability.

Safety and Site Access Assessment

Safe access is essential for routine maintenance, emergency response, and removal of pumps or equipment. We evaluate whether staff can access the station year-round, whether there is adequate space for crane trucks or bypass pumping, and whether confined-space entry points, ladders, walkways, and railings meet modern safety standards. Site circulation, lighting, and traffic considerations are reviewed. We also review site utilities such as electrical service reliability and availability of water for washdown or jetting.

Rehabilitate vs. Replace: How to Decide

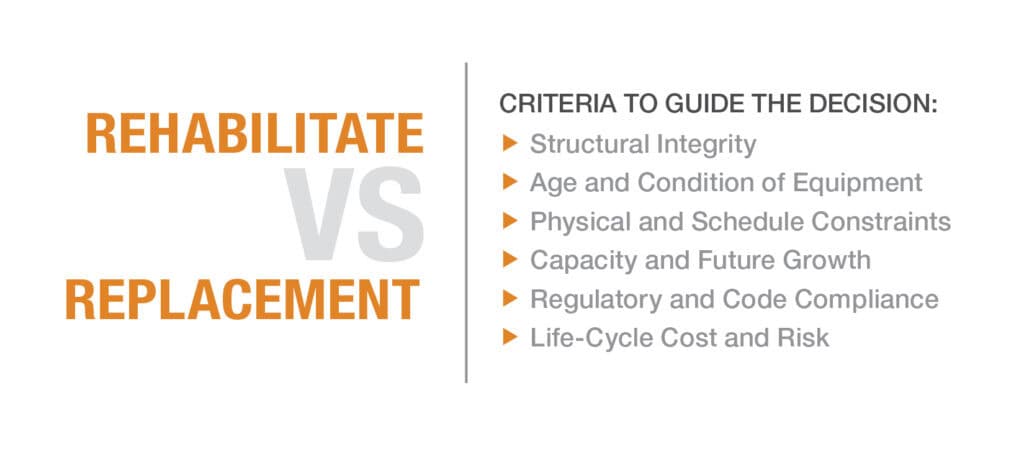

After assessment, each factor is scored and analyzed to create a defensible decision matrix. This framework compares life-cycle costs, schedule impacts, and risk exposure. The key criteria below help guide the decision.

1. Structural Integrity

If the wet well and associated lift station structural elements are structurally sound and the layout is functional, the station may be a strong candidate for rehab. But if the concrete is deteriorated beyond coating or repair, or if the station lacks space or access for modern equipment, replacement becomes the more practical solution.

2. Age and Condition of Equipment

Mechanical and electrical equipment nearing end of life, unsupported by manufacturers, or suffering chronic failures may suggest that full-scale replacement is the better value. Conversely, if the structure is solid and pumps, valves, or controls need only targeted repairs, rehabilitation can restore performance at a much lower cost.

3. Physical and Schedule Constraints

Some stations simply cannot be modified to meet modern hydraulic or spatial requirements. Undersized wet wells often lead to short-cycling, air entrainment, or poor pump hydraulics. Hydraulic Institute Standards require specific clearances and dimensions that older structures cannot always meet. If the site is too constrained to expand the wet well, add screens, or improve access, replacement is typically the only feasible option. Rehabilitation can often be completed faster and with less bypass pumping, making it preferable when operational downtime must be minimized.

4. Capacity and Future Growth

Population growth, redevelopment, and increased I&I can push older stations far beyond their intended operating range. If projected peak flows exceed what the existing station could be rehabilitated to meet, then rebuilding for higher capacity is naturally the best long-term choice.

5. Regulatory and Code Compliance

Some older lift stations cannot be brought into compliance with current codes without major structural changes. Requirements from NFPA 820, state redundancy rules, ventilation standards, flood protection criteria, and emergency power provisions can be difficult or impossible to meet in outdated or space-constrained facilities. When compliance upgrades exceed the physical limits of the existing station, replacement becomes the most practical solution.

6. Life-Cycle Cost and Risk

The final decision must balance upfront cost against long-term risk. In many cases, phased rehabilitation can extend asset life with minimal disruption. But if chronic failures, confined spaces, obsolete components, or access limitations continue to drive high O&M costs, a new station may deliver a lower total cost of ownership.

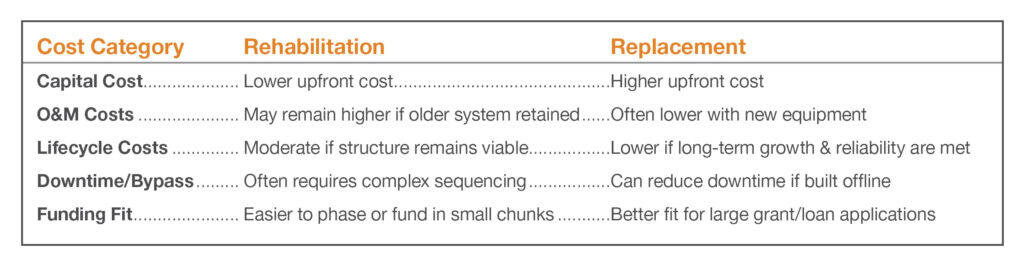

Rehab vs. Replacement – Cost Considerations

Building a Framework for Confident Decisions

Choosing between rehabilitation and replacement is not just an engineering judgment, it is a strategic investment decision that affects reliability, safety, and budget efficiency for years to come. By using a structured condition assessment and life-cycle cost analysis, communities can make informed, defensible decisions that extend asset life and optimize resources.

At HR Green, our municipal and wastewater engineering professionals partner with utilities across the country to deliver clear assessments, sound recommendations, and practical design solutions. Whether you are planning a small rehabilitation or a complete lift station replacement, our team can help you analyze risks, minimize downtime, and build infrastructure that serves your community for decades to come. Contact us today to learn more!