Challenge

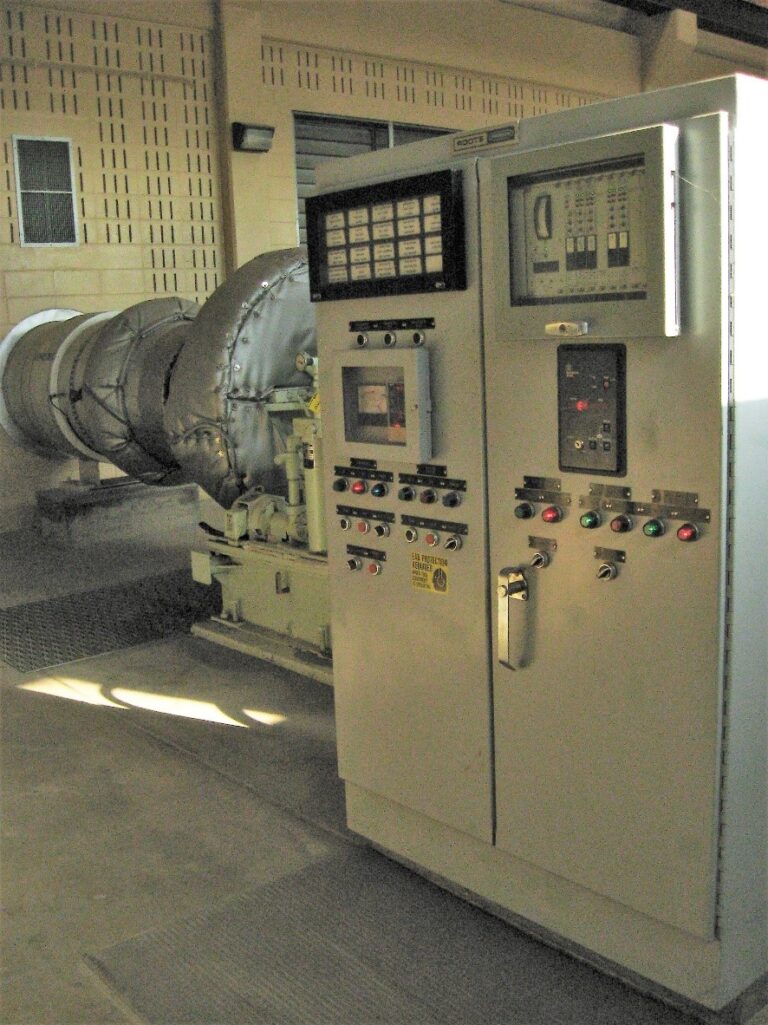

The Des Moines Metropolitan Wastewater Reclamation Facility, serving more than 500,000 residents, faced significant energy costs tied to its secondary treatment operations. Secondary treatment at the facility included the following items:

- 4 – 2,000 hp single stage blowers

- Design point – 27,000 scfm

- 4160 volts

- 6 – Aeration basins

- 4 Passes each

- Volume – 6.28 MG each

- 24 – Airflow meters (1 per pass)

- 24 – Airflow control valves (1 per pass)

- 24 – Dissolved oxygen meters (1 per pass)

The City sought a solution to optimize performance, reduce energy consumption, and manage operational costs without compromising treatment reliability.

Solution

HR Green conducted a comprehensive evaluation of multiple improvement scenarios, including variable frequency drives (VFDs) with and without automated control, soft starts with and without automated control, and controls and blower system modifications. Field testing confirmed blower capabilities for maintaining mixing during low DO demand. Based on these findings, the City implemented HR Green’s recommendation for a combination of advanced controls and blower modifications.

Key improvements included:

- Automatic blower controls to precisely match airflow demand, with tighter inlet guide vane control, expanded blower turndown range, and surge tolerance adjustments based on ambient conditions.

- Most open valve control routines to improve efficiency across the aeration basins.

- Revised startup sequences incorporating inlet guide vane closure at startup to reduce electrical spikes and improve equipment protection.

Benefit

The optimization reduced dual blower operation by 33%, significantly lowering energy demand. Demand charges were reduced by an estimated $6,000 per month, and annual energy savings are projected between $150,000 and $200,000. The improvements delivered a return on investment (ROI) in less than five years. Additionally, the City was recognized for its commitment to sustainable operations, receiving a $125,000 Mid-American Energy efficiency award.

Through strategic evaluation, field testing, and implementation of innovative controls, HR Green helped the Des Moines facility achieve measurable cost savings while enhancing operational efficiency and environmental stewardship.