The Environmental Protection Agency’s (EPA) recently proposed revisions to the effluent limitations guidelines (ELGs) for the Meat and Poultry Products (MPP) industry have set the stage for substantial changes to wastewater management practices nationwide. At HR Green, our environmental and engineering professionals are actively helping clients understand and prepare for these potential changes in MPP industry wastewater compliance. These updates are not only regulatory—they represent a push toward sustainable, modern industrial wastewater treatment strategies.

The Clean Water Act mandates that ELGs be updated to reflect advancements in pollution control technology. While the MPP category was first regulated in 1974, and updated in 2004, many of today’s processing facilities are operating under outdated standards that no longer reflect current environmental or public health expectations. The EPA’s new proposal—prompted in part by litigation from environmental groups—aims to address these gaps by expanding regulatory coverage, tightening nutrient limits, and introducing pretreatment standards for previously unregulated pollutants and discharge types.

Understanding the Scope of the Proposed ELG Rule

The proposed changes introduce three regulatory options for consideration, with Option 1 currently being the EPA’s preferred approach. Option 1 focuses on large direct and indirect dischargers and introduces new phosphorus and nitrogen limitations, as well as pretreatment standards for biochemical oxygen demand (BOD), total suspended solids (TSS), and oil and grease. Importantly, phosphorus would be regulated for the first time under the MPP ELG.

Approximately 850 of the 5,000 meat and poultry processing facilities nationwide would be directly impacted by Option 1, while Options 2 and 3 would extend the rule’s reach to even more facilities by lowering the production thresholds and expanding pretreatment requirements to additional categories.

These new requirements are significant not only in their scope but in the technical complexity they introduce. Facilities discharging directly to surface waters and those sending effluent to publicly owned treatment works (POTWs) may need to revisit and upgrade both physical infrastructure and operational practices to stay compliant.

What’s Changing and Why It Matters

The meat and poultry industry generates wastewater rich in organic matter, suspended solids, fats, and nutrients—particularly nitrogen and phosphorus. These pollutants can contribute to algal blooms, oxygen depletion in water bodies, and degradation of aquatic ecosystems. The proposed ELGs are designed to reduce these impacts by updating control technologies and expanding coverage.

For direct dischargers, the proposed rule introduces more stringent nitrogen limits based on biological treatment processes that support full denitrification, and phosphorus limits based on chemical removal. For indirect dischargers—facilities that send wastewater to municipal treatment plants—the new pretreatment standards would help reduce the burden on POTWs by requiring upstream removal of BOD, TSS, and oil and grease.

In all cases, facilities need to evaluate the applicability of the rule based on their production thresholds, discharge types, and facility subcategory. The proposed options also introduce new source performance standards (NSPS) and pretreatment standards for new sources (PSNS), which mirror the requirements for existing facilities under the new rules.

Wastewater Treatment Strategies

Implementing the proposed regulations will require careful evaluation of wastewater treatment systems. Facilities will need to explore:

Phosphorus Removal:

- Chemical addition: Facilities may use metal salts such as ferric chloride, aluminum sulfate (alum), or lime, often supplemented with polymers, to enhance phosphorus precipitation.

- Tertiary filters: Post-chemical treatment filters, including sand filters, ion-exchange units, or membrane systems, are viable for further phosphorus removal.

Conventional Pollutant Removal:

- Screening Systems: A critical first step used to remove large particulates and prevent equipment damage. Screened material often serves as raw material in rendering processes.

- Dissolved Air Flotation (DAF): Widely used in primary treatment processes, DAF systems efficiently remove oil, grease, and suspended solids by floating them to the surface for removal. In some facilities, such as renderers, solids captured here may be recycled to the facility as raw materials.

- Chemical Addition: Chemicals such as polymers, flocculants, and phosphorus enhance pollutant removal effectiveness, particularly when integrated into DAF processes. However, caution is needed if solids are recycled for rendering to avoid contaminating raw materials.

Operational and Cost Impacts of ELG Compliance

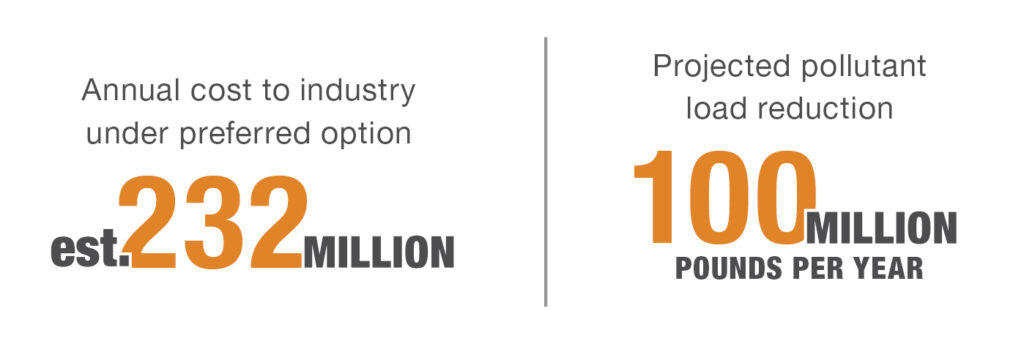

The cost to the industry under the EPA’s preferred option is estimated at $232 million annually, with a projected pollutant load reduction of 100 million pounds per year. While the environmental benefits are clear, the burden on processing facilities—particularly small and mid-sized operations—should not be underestimated.

Operators will need to assess whether they fall under the thresholds defined in each regulatory option and, if so, evaluate how their current treatment systems compare to the Best Available Technology (BAT), Best Practicable Control Technology (BPT), and other benchmarks defined in the rule. For direct dischargers, this may involve a reconfiguration of biological processes or the installation of tertiary treatment systems. For indirect dischargers, pretreatment upgrades and coordination with local POTWs may be necessary.

Next Steps for the MPP Industry

The EPA is accepting comments on the proposed rule and its options, and barring any additional delays, a final rule is expected by August 2025. Facilities should begin preparing now by:

- Determining Applicability: Review current operations to identify whether your facility meets the production thresholds and discharge profiles addressed by the proposed rule.

- Performing a Gap Analysis: Compare existing treatment capabilities with the requirements of each regulatory option under consideration.

- Exploring Treatment Alternatives: Investigate feasible and scalable treatment solutions for nutrient removal and pretreatment.

- Planning for Capital Investments: Begin financial modeling and schedule planning for potential design and construction projects.

- Engaging with Engineering Partners: Collaborate with engineers who are actively tracking the ELG process and can provide data-driven assessments to support facility readiness.

Learn how HR Green has helped clients navigate challenges with forward-thinking wastewater solutions:

- National Beef Wastewater Treatment + Reuse Facility

- Minnesota Industrial Wastewater Treatment Plant Design

Planning for a Cleaner, Compliant Future in Wastewater

The proposed changes to the Meat and Poultry Products ELGs represent a significant shift in how the industry approaches wastewater treatment. While the challenges are considerable, the benefits, in terms of environmental performance, operational resilience, and public trust, make this a critical moment for planning and innovation.

At HR Green, we’re working closely with MPP facilities to assess the proposed rule’s implications and identify practical paths forward. Early preparation is key—facilities that act proactively will find themselves well-positioned to thrive under the new environmental standards.

Contact us today for professional guidance on EPA ELG compliance!