Wastewater treatment plants (WWTPs) face rising expenses from chemical prices, electricity rates, and fixed labor costs. Facility managers and operators can ease these financial pressures by improving wastewater treatment efficiency with strategies that focus on chemical optimization, pump efficiency, and blower energy savings.

Understanding Wastewater Treatment Cost Drivers

While fixed costs such as labor, fuel, and basic chemical and electricity rates are challenging to control, wastewater facility managers have opportunities to impact costs through:

- Chemical usage optimization

- Electrical efficiency improvements

Chemicals and energy represent approximately 60-70% of the total operations and maintenance (O&M) expenses at a WWTP. The cost percentage will be significantly higher for advanced treatment processes. Managing inefficiencies in these areas can yield substantial cost savings.

Reducing Chemical Costs in Wastewater Treatment Plants

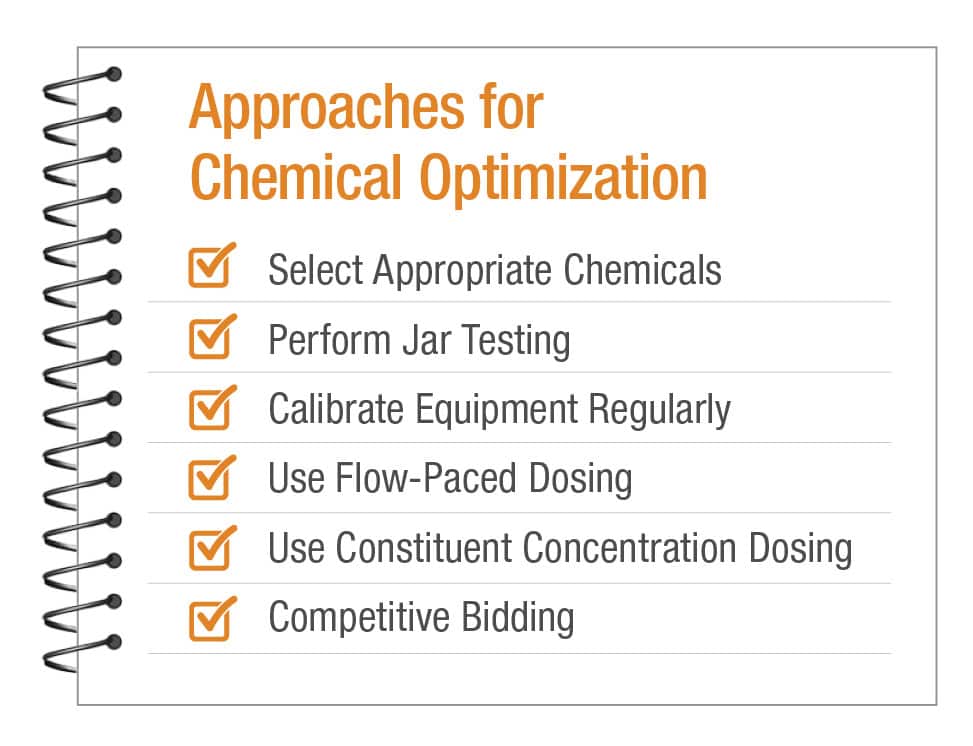

Chemical costs escalate when treatment chemicals are overdosed or misused. Operators may inadvertently use peak dosage levels in lieu of dosage control, adjust the dosage on influent concentration changes, or continue using dosing rates when chemical changes occur, all leading to unnecessary expenditures. Regularly reviewing chemical use practices is recommended. Optimizing chemical dosages requires multiple approaches:

- Select Appropriate Chemicals: Consider chemical effectiveness, side effects, storage requirements, availability, and safety.

- Perform Jar Testing: Jar testing will determine the correct dosage to achieve removal efficiencies and estimate solids precipitation/accumulation to be considered. Economic feasibility based on the findings will support the selection process.

- Calibrate Equipment Regularly: Maintain accurate dosing through precise calibration. Chemical metering should be checked regularly through the use of a calibration column. Pump efficiency will change over time due to many factors, including wear, part changes, etc. Calibration adjustments will true up the dosage to match testing.

- Use Flow-Paced Dosing: Adjust chemical feed rates according to real-time plant flow rates to prevent chemical waste during low-flow periods. Pacing the chemical pump should be part of any plant system as most of the monitoring and feedback are already available.

- Use Constituent Concentration Dosing: If the chemical constituent you are trying to remove is variable in the flow stream, additional dosing control can be accomplished with real-time monitoring feedback to control the pump.

- Competitive Bidding: Regularly re-quote chemical prices to support cost competitiveness.

These optimization techniques can get advanced, requiring additional equipment and controls to be integrated. Economic feasibility should be reviewed to justify capital expenditure.

Improving Pumping Efficiency in WWTPs

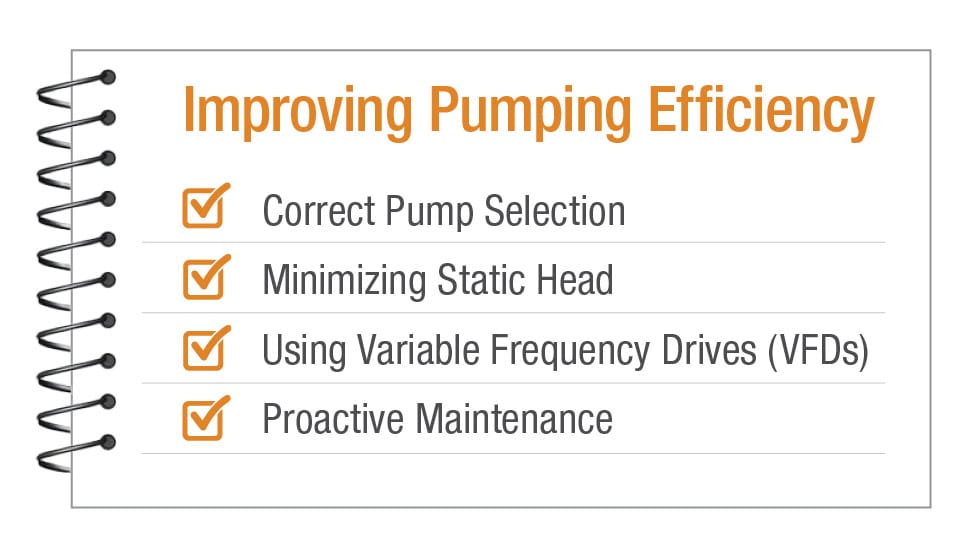

Pumping systems account for a significant amount of energy use. Optimizing pump performance has many advantages for pump longevity, maintenance, treatment or downstream equipment. Specifically, energy efficiency in pumping applications involves:

- Correct Pump Selection: Select pumps based on optimal efficiency points, best operation ranges, and the manufacturer’s efficiency curves.

- Minimizing Static Head: Maintain higher wet well levels to reduce pump energy consumption by decreasing static head.

- Using Variable Frequency Drives (VFDs): Employ VFDs to match pumping rates closely with inflow, significantly reducing horsepower requirements and startup demand charges.

- Proactive Maintenance: Regularly maintain pumps to prevent energy loss due to mechanical wear and plugging, avoiding costly repairs and emergency shutdowns.

Enhancing WWTP Blower Efficiency

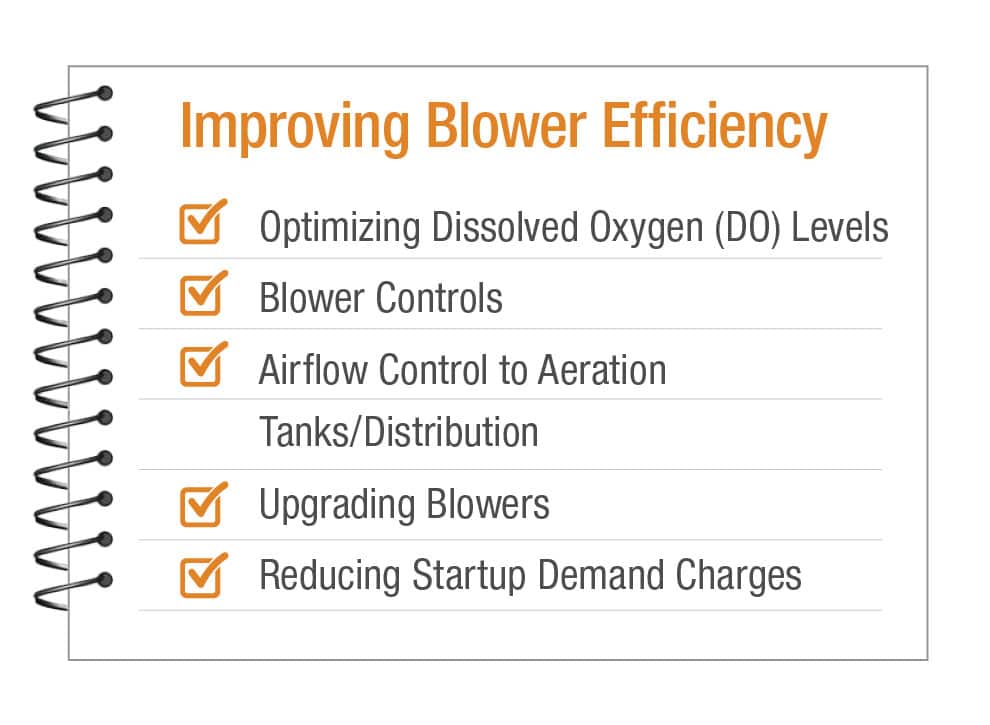

Blowers used for aeration of secondary treatment typically represent a majority of the power consumption at WWTP. Similarly to pump efficiency strategies, blower efficiency approaches include:

- Optimizing Dissolved Oxygen (DO) Levels: Adjust blower operation to maintain DO at required levels, avoiding over-aeration and associated energy waste. Some plants have realized sufficient treatment levels at reduced DO levels, leading to reduced energy consumption.

- Blower Controls: Implement feedback control for aeration blower equipment to maintain delivered air/oxygen matching the process need. The controls will adjust power demands of the equipment using VFDs or airflow throttling valves that will unload the equipment to modulate air delivery. Feedback loops for aeration include monitoring of DO, oxidation-reduction potential (ORP), and ammonia feedback loops.

- Airflow Control to Aeration Tanks/Distribution: Optimizing valve position throughout the distribution system can also maintain the lowest backpressure to maintain delivery of air. Most open valve routines can be incorporated to mitigate any valve “bottlenecks” that increase backpressure, resulting in higher energy consumption.

- Upgrading Blowers: Once older equipment has run through its life cycle, replacements should consider higher efficiency units such as turbo blowers.

- Reducing Startup Demand Charges: Electrically driven equipment requires high power demands to start. The electrical system is required to be designed to deliver that power for satisfactory operation. Power users may be charged a “demand” charge or other similarly named charge to have the power available for starting operations. These charges can be significant, depending on the type of equipment used. One strategy to minimize the charges includes operating equipment continuously at lower speeds to minimize frequent startups and associated electrical surcharges. Other strategies include capital investments in electrical equipment to minimize startup currents, such as soft starters, reduced voltage starters, or variable frequency drives that can be programmed to meet specific startup requirements—ultimately helping reduce demand charges.

Put to Action: Wastewater Treatment Case Studies

Faced with the challenge of replacing an aging wastewater treatment facility and meeting rising demand, Missouri City, Texas partnered with HR Green as an Owner’s Advisor on the Steep Bank Flat Bank Wastewater Treatment Plant expansion. The upgrades increased capacity by 50% without new treatment structures, saving the city approximately $176,000 annually through improved efficiency.

The Des Moines Metropolitan Wastewater Reclamation Facility faced rising energy costs tied to operating its large aeration system that was serving more than 500,000 residents. By implementing advanced blower control upgrades, including automatic airflow adjustments, optimized startup routines, and fine-tuned inlet guide vanes, the City cut dual blower use by 33%, reduced demand charges by $6,000 per month, and achieved annual energy savings of nearly $200,000.

Key Takeaways for Wastewater Treatment Plant Operators and Managers

Wastewater operations costs can be reviewed for substantial opportunities for fixed cost reductions through targeted chemical usage and energy efficiency strategies:

- Optimize chemical dosing based on real-time plant conditions.

- Select and maintain pumps and blowers for peak operational efficiency.

- Utilize technology like VFDs and blower controls to reduce energy consumption.

By implementing these proactive practices, utility operators and managers can effectively meet increasing treatment demands without exceeding operational budgets, ensuring sustainability and fiscal responsibility for their communities.

Contact us today to learn how your facility can achieve cost savings through improved wastewater treatment efficiency.