Municipal lift stations, sometimes referred to as pumping stations, play a vital role in wastewater collection systems by transferring sewage from lower to higher elevations when gravity flow alone is not sufficient. While lift stations help reduce infrastructure costs through shallower sewers and smaller pipes, they also introduce a higher level of operational complexity. Each lift station requires properly functioning components such as buildings, wet wells, pumps, power systems, controls, and piping to operate efficiently.

Without consistent maintenance and modern design provisions, these stations can quickly become weak points in the collection system. At HR Green, we believe that smart engineering solutions, such as incorporating pumping redundancy, backup power, and alarm systems, are essential to maintaining reliability and efficiency.

Lift station rehabilitation is often driven by a set of common issues. Addressing these challenges effectively can help municipalities improve system performance and extend the life of critical infrastructure.

Common Issues Driving Rehabilitation of Municipal Lift Stations

1. Aging Equipment and Infrastructure

Many municipal lift stations were constructed between 1975 and 1990, meaning that much of the equipment now exceeds 40 years of service life. Over time, pumps, motors, valves, controls, and concrete structures degrade due to corrosion, hydrogen sulfide exposure, and general wear. Even if a station is technically operational, it can be fragile, costly to maintain, and at increased risk of sudden failure or noncompliance with regulatory standards.

These aging components make rehabilitation or replacement not just a consideration, but a necessity. As utilities face growing maintenance costs and rising risks, many are proactively investing in system upgrades to preserve reliability for the next generation.

2. Obsolete Technology

Older lift stations often rely on constant-speed pumps with minimal instrumentation or control features. These systems tend to operate on basic float mechanisms, resulting in frequent pump cycling and increased wear. Electrical systems can lack surge protection, arc-flash labeling, and critical safety features.

Controls in many older facilities still depend on mechanical timers or relay logic, which offer no flexibility, programming, historical data collection, and limited ability to predict failure. Without modern automation or SCADA integration, operators are left with limited visibility, minimal control, and frequent emergency callouts. Upgrading to variable frequency drives (VFDs), modern control panels, and real-time data monitoring can transform operational efficiency and safety. By applying AI-based predictive analytics to lift station data, utilities can shift from reactive maintenance driven by alarms to proactive maintenance driven by equipment condition.

3. Capacity and Flow Changes

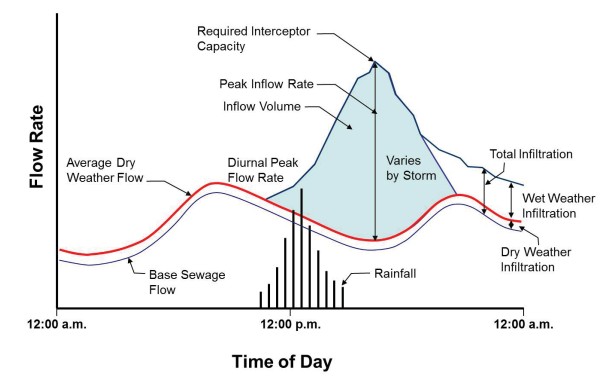

As communities grow, wastewater systems face increased demand. Many lift stations were originally designed for smaller populations and lower infiltration and inflow (I&I) levels. (See Flow Rate versus Time of Day figure.) Today, population growth, upstream development, and aging infrastructure often result in higher peak flows—sometimes five to ten times higher than dry-weather flow rates.

Wet-weather events can further exacerbate these challenges by introducing inflow from roof drains, sump pumps, and open cleanouts. When upstream improvements push more wastewater into older downstream stations, it can create system bottlenecks and overflows. Proper planning and flow modeling during rehabilitation can help scale the system appropriately to meet demand and minimize the risk of service disruptions.

4. Odor Issues and Community Impact

Odor complaints are among the most frequent triggers for lift station rehabilitation projects. Many older stations were constructed before modern odor control systems became standard, and the increased implementation of low‑flow, water‑efficient fixtures has further compounded the issue by reducing flows and extending wastewater transit times, conditions that increase septicity. As development continues to grow around these facilities, the public’s tolerance for nuisance odors decreases.

Hydrogen sulfide formation, long retention times, and stagnant flow conditions often lead to unpleasant smells that can create community and political pressure. Incorporating odor control systems, chemical dosing, and improved wet well design can significantly reduce these issues, enhance system performance, and restore community trust.

5. Maintenance Limitations and Hidden Costs

Even functional lift stations can be costly and hazardous to maintain if they lack accessibility and proper design features. Many older facilities have limited access for vactor trucks or cranes, no bypass piping, and no provisions for safe and convenient equipment removal. As a result, maintenance tasks become more time-consuming, hazardous, and expensive.

Another common issue is poor wet well design, such as flat bottoms or oversized basins that allow solids, rags, and grease to accumulate. This buildup leads to clogged pumps, foul odors, and frequent manual cleaning. Rehabilitation that prioritizes maintenance-friendly design helps utilities reduce downtime and long-term operational costs.

Transform Lift Stations into Reliable Community Assets

Effective lift station rehabilitation goes beyond replacing old components. It involves re-engineering for greater reliability, modernizing technology, improving safety, and preparing for future growth. By addressing critical issues such as aging infrastructure, outdated controls, flow variability, odor, and maintenance inefficiencies, municipalities can transform lift stations from operational vulnerabilities into dependable community assets.

At HR Green, our wastewater and municipal engineering professionals partner with communities nationwide to assess, design, and implement lift station rehabilitation solutions that meet regulatory standards, improve performance, and extend the life of critical infrastructure.

If your community is considering a lift station upgrade or rehabilitation project, contact HR Green to learn how our team can help improve system reliability, reduce maintenance costs, and enhance wastewater collection efficiency.